The high lift system is one of the most mechanically complex systems on the aircraft.

The system comprises a complex series of mechanical drive-shafts, actuators and linkages that deploy the slat and flap systems for take-off and landing.

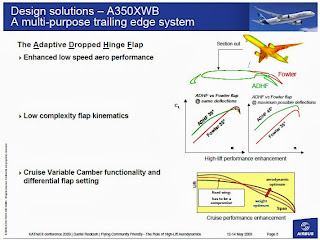

Due to the potential to generate roll asymmetry that could not be controlled if deflections were different between left and right hand wings, the systems also comprises a complex detection system to lock the slats and flaps in place if a failure is detected. The A350 XWB high lift system also includes new technology with the Advanced Drop Hinge Flap (ADHF) system.

A new trailing-edge high-lift system has been adopted with an advanced dropped-hinge flap (similar to that of the A380), which permits the gap between the trailing edge and the flap to be closed with the spoiler.

A stub flap is subject to simulated air loads generated by pneumatic cylinder being compressed by a hydraulically operated frame.

The Airbus high lift ‘zero’ rig, located in Bremen (Germany), consists of a complete left hand ‘wing’ with all the systems that will be found installed on MSN001. The aircraft structure is not present and is replaced by a steel structure to allow the system to be installed and operated. The right hand wing is simulated by a high technology electro-hydraulic brake system. This test rig is used to perform many safety tests prior to the first flight to ensure safety. A number of tests are performed on this rig that would be too dangerous to perform in flight – deliberate failures of shafts or drive links, for example.

The A350 XWB high lift ‘zero’ has been operational since late 2011 and was upgraded to full MSN001 configuration with real flaps installed in September 2012

The new high-lift flap, which has been patented by Airbus, is a dropped hinge design and consists of a beam with a rotation point. Designated as the "advanced dropped hinge flap," it is simpler than a conventional flap and requires less moving parts, resulting in a half tonne weight reduction. It is also easier and less costly to maintain.

It is good that technology has improved the tools that can easily analyze what better can be done to improve the efficiency of the a particular equipment or part of a machine.

ReplyDeleteThanks

Bruce Hammerson

Hydraulic Hammers

You have shared a great information about Flap Hinge and Lift Off Hinge.Which are very informative for us.Thanks

ReplyDeleteThis is an intresting blog that you have posted, you shares a lot of things about Hinge Suppliers, Continuous Hinges Stainless Hinges.

ReplyDeleteWhich are very informative for us. Thanks

Wow very interesting information provide its such a nice and help full information provide thank you so much dude James Bond Tuxedo

ReplyDeleteHy I'm Designer For Customize Leather Jackets. Please Visit Our Website. The Get Down Brother Cotton & Polyester Jacket

ReplyDeleteLED Mini Turn Signals

ReplyDeleteWe have you spoiled for options. Our website consists of jackets for all genders, shapes, and sizes. We only deal in 100 percent pure genuine and faux leather. Our panel of jackets includes sheepskin, goatskin, and cow skinned leather. Our variety makes us a unique and trendy option for you to choose from. Moreover, We accept customized designs that can satisfy the need of our customers. Tesla Model S Plaid Elon Musk Leather Jacket

ReplyDeleteHARDCORE CYCLES was started in the Greater Philadelphia area by a group of tight friends with a passion for V-Twin performance aftermarket parts.Visit our Website Thanks

ReplyDeleteDragshocks

Shop this best Super Leather quality The Man From Toronto Woody Harrelson Black Leather Jacket For men SHOP NOW

ReplyDeleteEverest - Premium Series PP 083

ReplyDeleteWe’re JEEM. A new-age digital-first brand, committed to making travel easy, efficient, and tasteful for you.

We are a company led by individuals from diverse backgrounds but have one thing in common—their love for travel.

A couple of years ago, at an international terminal waiting for our luggage on the baggage belt, we realized how monotonous every bag looked. This seemed like an opportunity to break the clutter, and it led to the creation of a brand driven by innovation.

Every piece created at JEEM is designed and engineered to set you apart.