Public news about the A350 XWB collected in the web. Follow these and more news in Twitter @A350Blog

21 August 2013

A350 XWB is the first Airbus aircraft with cargo fire protection as combination of Halon1301 and Nitrogen Enriched Air (NEA).

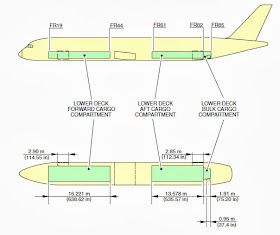

The lower half of the cross section is designed around the cargo compartments and the loading system. The A350-900 has three compartments, i.e.: the forward, aft and bulk compartments and can load up to 36 LD3 containers or 11 standard pallets of 96 inches. Special equipment is available for the transport of live animals, perishable goods, heavy pallets and vehicles.

To minimize the aircraft turn around time, the A350 XWB offers a high level of cargo hold capability and flexibility; 2 wide cargo doors and a Cargo Loading System (CLS) compatible with most lower deck cargo containers and pallet standards, allowing interlining operations, ease the loading.

In frame of the A350XWB development, the current flow-metered Halon 1301 fire extinguishing bottle for cargo bay long term fire suppression has been deleted, and Nitrogen Enriched Air (NEA) produced by the Inert Gas Generating System (IGGS) -as part of the Fuel Tank Inerting System (FTIS)- is used instead.

This evolution has different benefits because is the first step to halon-free aircraft –the A350 is “green-aircraft” (less halon). Other benefits is a 20-45 kg weight saving allowing an unlimited ETOPS and an aircraft level architecture synergy.

The weight reduction with respect to the conventional system depends on the ETOPS configuration: up to 20 kg are envisaged for 195 min diversion time and up to 45 kg are envisaged for 360 min diversion time.

Effectiveness of a combined Halon1301 / NEA system has been shown.

Based on the presentation “A350XWB Cargo Inerting Function” done within the International Aircraft Systems Fire Protection Working Group by Airbus.

No comments:

Post a Comment