Customers are particularly impressed with Airbus' progress on the design of flexibility and reconfiguration enablers when being presented the cabin design progress.

"The customers demonstrated the functioning principles and were delighted at the response," Jonathan Norris, head of cabin and cargo A350 programme says. "The airlines were particularly happy to see this aspect being included up front in the design process." The ability to reconfigure the interior of the A350 quickly and simply across galleys, lavatories and all passenger classes, is a priority, says Ilke Calis who is in charge of enabler development. "Enablers are the key interfaces between cabin components - standardising them will reduce installation and reconfiguration lead times for airlines and thus save them money," he says.

Click the image to watch a video

A team of 20 from cabin engineering, the final assembly line (FAL) and external suppliers has been working to develop prototype enablers, each of which has been videoed and timed during trial installations in the cabin mock-up. The team also performed an extensive internal benchmark with other FALs, with for example, the monument upper attachments chosen coming from the A380 cabin. "We are very pleased with results so far," Ilke concludes. "We are very close to our time targets and final selections and are currently fine tuning our concepts. We have made significant architecture advances too, such as the new seat-to-seat connection, combining the power and data cable in a single harness, meaning it is considerably lighter and more reliable."

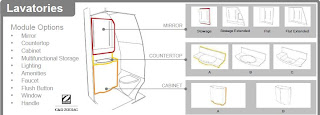

The modular cabin layout can be reconfigured overnight to allow airlines flexibility to adapt for seasonal needs.